The seabed environment has always posed unique challenges for offshore developers, whether in pursuit of O&G reserves, renewable energy, or marine minerals. The build-out of safe and sustainable offshore infrastructure is fundamentally reliant on robust geotechnical analysis of seabed soil and bedrock conditions. While initially born out of onshore geotechnical practices, today, offshore geotechnics is a standalone discipline governed by independent codes and technical standards. After all, offshore assets—which typically tower hundreds of meters above their foundations—are subject to greater environmental lateral loads (moment loading relative to structure weight caused by wind, waves, and currents) and a wider range of location-specific geohazards than their land-based counterparts.

These highly variable and often hazardous marine conditions make thorough in situ site investigation a fundamental part of offshore planning, as any significant modification requirements during construction phase are usually unfeasible or financially crippling. Therefore, as offshore operators look to venture into deeper waters, often in the face of mounting environmental concerns, the urgency for highly experienced marine geotechnical expertise has never been greater. And while the offshore geotechnical industry has always been a relatively conservative one—perhaps unsurprisingly so given the stakes—there are signs that recent advances in geotechnical engineering are beginning to rewrite the subsea survey playbook and challenge the long-established order of geotechnical service providers.

GROUND-BREAKING TOOLKIT

Whether for hydrographic, geophysical, or geotechnical analysis, ever smarter instrumentation enables us to render increasingly precise, real-time data. It was an unwavering and shared commitment to data quality that led a select team of pioneering geoengineers to start Bluefield Geoservices in 2018, with a mission to redefine geoscientific frontiers by bringing to market a suite of specialist geotechnical products and services. As well as offering the equipment and personnel for rigorous offshore data acquisition, processing, analysis, QC, and site management, Bluefield Geoservices has made significant investments in proprietary custom geotechnologies, such as the ROVcone and BOXcone, for a range of complex seabed situations.

These innovations are the result of the considerable real-world insight and analysis that the Bluefield team has gleaned while performing in situ testing and site investigation around the world, including in the Caspian Sea, the Gulf of Mexico, North Sea, and in offshore regions of Australasia. When it comes to oilfield development, regardless of depth, it is essential to have the right toolkit to perform numerous CPT and sample tests within a tightly defined area. The ROVcone not only allows for precision positioning, but also the ability to fly the ROV to the next survey point without the need to retrieve the equipment between each test, resulting in significant operational efficiency.

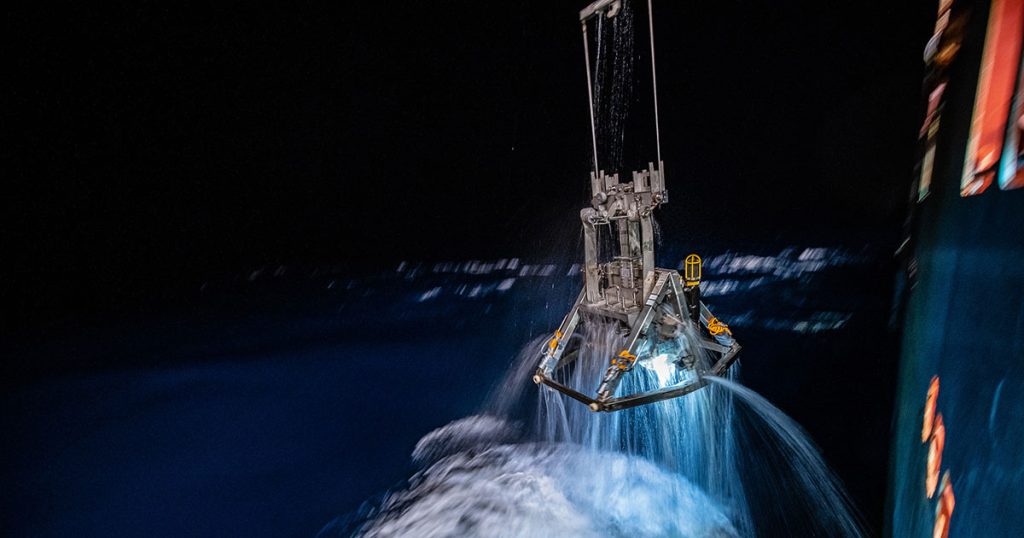

The ROVcone system enables operators to deploy a lightweight unit that still delivers 1,000 kg push force for in situ soil testing or sampling and can be paired with any Work Class ROV or similar. The wire-free (acoustic) real-time communications between the penetrometer and the ROV eliminates cabling, reduces snag hazards, and speeds up installation and removal to/from the ROV. The ROVcone can also be operated in a standalone frame as a crane or an A-frame-deployed seabed unit.

The BOXcone system is a specialized in situ testing tool designed to interface with a box core sample box. Designed to meet the requirements of a lightweight unit for use on deck, the BOXcone delivers precision-controlled push force and can be deployed on any box core with a removable box. The system is designed for in situ testing including CPT, T-bar, ball cone penetrometer, lab vane, and plate load testing, as well as push-in sub-sampling. Other probes can also be supplied, such as thermal conductivity. It is suitable for use in all soils capable of being sampled by a box core system.

Both the ROVcone and BOXcone are ideal for route surveys, pipeline studies, subsea developments, drill cutting surveys and marine mining site investigations.

SONIC DRILLING TECHNOLOGY

SONIC DRILLING TECHNOLOGY

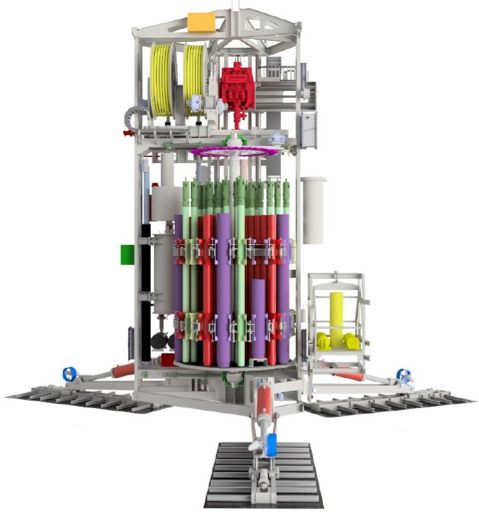

Another recent addition to the exclusive Bluefield Geoservices toolkit is the SWORD, the world’s most advanced, heavy duty and remotely operated subsea drilling and geotechnical site investigation system. The SWORD (Sonic Wireline-Operated Remote Drill) incorporates sonic drilling technology into a seafloor sampling tool. The drill rig is powered by a Sonic-Samp-Drill (SSD) compact roto-sonic drilling drive, together with full size drill pipe strings, which are automatically assembled at the seabed from a storage carousel. The rig is fully integrated with an A.P. van den Berg (APB) in situ CPT testing system and NGI designed push and piston samplers. It uses high-frequency vibrations to push casing sections, drill rods and sampling tubes into the seafloor.

Unlike conventional drilling vessel assets, the SWORD is remotely operated and deployed directly on the seabed. Not only does this eliminate the challenges associated with heave impact and rough sea states, the SWORD can be controlled from any suitable medium or large marine asset (as opposed to being drill ship dependent).

ENABLING REMOTE OPERATIONS

As developers look to leverage the safety and cost benefits associated with progressively autonomous—or at least crewless—offshore operations, Bluefield Geoservices is also working on a number of new systems designed to streamline resources needed for rigorous in situ geotechnical investigation. One such tool is the team’s remotely operated CPT platform, depth rated to 3,000 meters, which allows for “over the horizon” control by shore-based technicians. While the device still requires personnel onsite for system calibration, deployment, and the collection of physical samples, the incorporation of automated hardware like this does allow for a significant down-manning of at-sea operations and, subsequently, the reduction of associated carbon emissions.

EXPLORING NEW FRONTIERS

Naturally, site investigation methods are location specific. For example, the compacted sands found in the North Sea require a different approach to the carbonate sediments found offshore Brazil or the ultra-high plasticity soft clays offshore West Africa. This is why offshore geotechnical proficiency and in-field experience is so critical as developers look to explore new frontiers where little or no historical data exist.

Plans for the U.S. offshore wind build-out call for a fresh look at geotechnical service providers. While European nations and operators have spent the past 30-plus years developing their offshore wind capabilities, the U.S. has lagged behind. But recent state pledges—in Maryland, Massachusetts, New Jersey, New York, Rhode Island—have triggered action to scale and develop a local supply chain that will, according to the American Wind Energy Association (AWEA), create up to 83,000 jobs by 2030.

This growing need among operators to explore seabed conditions in greenfield sites spurred on Bluefield Geoservices’ expansion from its UK-based HQ to the Americas in late 2019, opening offices in Rhode Island and Florida. The group’s technologies are now available for rapid deployment, both in the country’s northeast and the Gulf of Mexico.

Ocean mining, an offshore activity that has attracted considerable scientific interest over the decades but negligible commercial progress, is another “new” frontier that is ever reliant on robust deep-sea geotechnical data and know-how. We have long known that the seabed, at depths of up to 6,000 meters, is home to an abundance of rare-earth elements and prized metals—including nickel and cobalt—needed to build-out a more sustainable future. In short, the very inputs needed to invest in future offshore infrastructure.

Generally speaking, the harvesting of polymetallic nodules, while only one method of extraction, looks like the most feasible route to market in the short- to mid-term. The greatest accumulations of these potato-sized rock concretions are found in the Pacific Ocean’s Clarion Clipperton Zone (CCZ), where commercial and state-led entities continue to carry out their environmental due diligence and test their nodule collectors. Studies suggest that we are fast approaching a point of both economic and environmental viability with regards to mining seabed deposits on an industrial scale.

In 2019/20, Bluefield staff played an integral role in a number of key ocean mining exploration campaigns in the CCZ, contracted by Canada-based battery start-up DeepGreen Metals Inc. Six team members performed in situ data acquisition and on-deck geotechnical analysis for Campaigns 6a and 6b, as well as providing follow up services to assist with the supervision of laboratory work and reporting. Future plans include the deployment of the ROVcone on a deep-water Work Class ROV to gather additional samples.

A CUSTOM ENGINEERED APPROACH

A CUSTOM ENGINEERED APPROACH

It is an unrelenting urge to advance subsea engineering R&D that unifies a tight team that, collectively, represents a level of subject matter authority that belies headcount. Bluefield’s roster is an extensive roll call of projects involving subsea soil sampling, testing, and drilling equipment. It is this hands-on, multi-disciplinary experience that gives Bluefield clients a distinct advantage when seeking to conceptualize, procure, or upgrade their subsea survey capabilities.

The Bluefield approach tends to be project specific, which helps recalibrate R&D efforts towards challenging the status quo; balancing what is possible with what is practical is the first step in redefining how innovative subsea technology can transform site investigation and ultimately guide 21st century offshore construction. By collaborating with industry partners from the offset, Bluefield GeoEngineers are equipped to offer guidance on foundation analyses for subsea structures, offshore platforms, renewable energy infrastructure, pipeline stabilization, mooring systems, and marine mining machinery.

The team is also working on a number of next-generation foundation and anchoring concepts for offshore structures of tomorrow. Current projects include robotically installed foundations for offshore floating wind anchors and pipeline stabilization, based around micropiling and the use of subsea robotics to provide tensile capacity and lateral restraint. Further in-house capabilities include 3D modelling and analysis of structures and computational fluid dynamics for the development of innovative tooling for jetting and profiling the seabed.

DEALING WITH THE PAST, TOMORROW

However, amid the age of decommissioning, the development of offshore geotechnical products and services will be as much about the past as it is the future. As unprecedented numbers of offshore assets approach the end of their production lifecycle in the 2020s, commentators predict a surge in demand for site investigation services that prioritize the planning of safe, cost-effective, and environmentally responsible decommissioning practices.

Many offshore assets have, over the decades, become integral to their surrounding marine environment; their removal could destroy flourishing marine ecosystems. For this reason, operators are turning to accomplished providers of noninvasive survey technologies to acquire the most comprehensive data and analysis available. Bluefield Geoservices, through strategic partnerships, has also broadened its range of services to incorporate geophysical and environmental survey—including physical sampling; geophysical and hydrographic surveys; offshore O&G EBSs and monitoring; habitat mapping; and Environmental Impact Studies—to serve the international offshore energy markets with a complementary suite of specialist services.

Establishing best practice in a time of unprecedented technological advancement will no doubt be a challenge, and one that will require an open and flexible mindset among stakeholders and policymakers. But challenge, and more specifically the task of guaranteeing ever more stringent offshore geotechnical understanding, is what Bluefield Geoservices thrives on.

This article was featured in the January 2021 Issue of Ocean News & Technology (ON&T), Focus: The Essential 2021 Offshore Toolkit.